clockwise33

New York Giants Fanatic

- Location

- NJ

After about 15 years of ownership, I decided it was time to attempt an LSD install, along with F&R sway bars and 034 subframe pucks. Below are some pictures and insights from the experience:

I decided to go with the Mfactory helical LSD due to the price (<$800 shipped) and having read a lot of positive reviews on various platforms. I was happy with the apparent quality of unit:

My 125,000 mile 02Q looks perfect inside. No oil sludge or unusual wear. I've used OEM fluid, with 1 change at about 90,00 miles.

This being a 2006, I had the brass shift forks. I had originally ordered the steel forks, but was told that they were back ordered and would delay my project at least 2 weeks, I decided to go another route and strengthen the original forks as seen here: https://forums.tdiclub.com/index.php?threads/how-to-02m-02q-lsd-install.310279/. I replaced the failure prone rivets with 12.9 M8 cap screws, grinded the heads and sloppily welded to prevent loosening:

Drilled out the rivets on the stock diff. Lesson learned: start with the small pilot hole to help guide the larger bit (1/2" cobalt). Then fitted the ring gear to the Mfactory. Torqued the supplied hardware to 70ft-lbs with red loctite.

Checked endplay with no shim. Ended up being able to use the original shim (0.95mm). This pointed to the quality machining of the Mfactory, having the same bearing locations as the factory to the nearest 0.05mm.

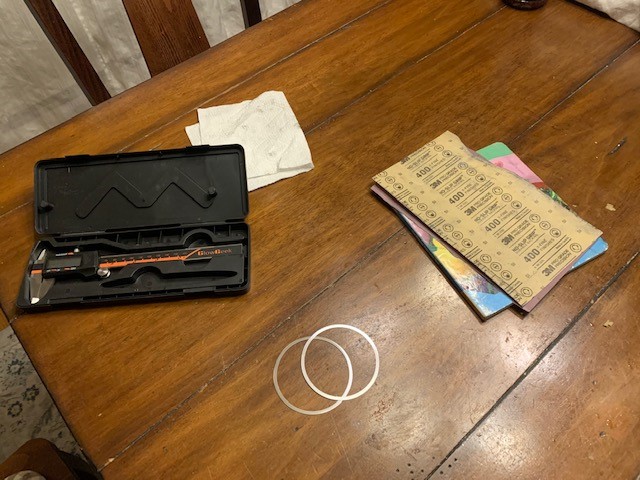

Now on the one issue I discovered in my 02Q - the input shaft bearing. This is a common problem frequently discussed in MK4 R32 forums. On 02M and early 02Q units, the large ball bearing on the outer end of the input shaft has a tendency to have the outer bearing spin in the case. This leads to wear of the aluminum case which eventually allows the bearing to have axial play. In my case the input shaft was able to move in and out about 1/16". This resulted is hard shifting in and out of 1st and 2nd gear. If left unchecked, the case would continue to wear until the input shaft gear faces begin to grind on the alternating 1-4 and 5-6 stack gears, this is commonly referred to as the "02M death rattle." Later 02Q's have steel washers on either end of this bearing which seemed to prevent the issue. I fixed the issue by first installing one shim (0.65mm) then measuring the remaining play (in my case 0.25mm). So I needed 0.9mm shimming to eliminate play. I accomplished that by pickup another OEM shim and sanded both shims to 0.45mm. This eliminated the axial play and I applied Loctite 680 bearing retaining compound to the outside of the bearing to prevent further spinning which should permanently fix the condition.

All in all it was a really fun project. I don't have much of a review of the results yet because the car now badly needs an alignment (also replaced tie-rod ends) and I haven't yet put on my summer wheels.

On the 034 subframe mount - it is ridiculous that this mount is marketed as a solution for street cars. I had extreme vibration on 1st gear take off. I thought my glovebox was going to fall off. I drilled several relief holes in the rubber which calmed it down to the point that it's livable for now.

I decided to go with the Mfactory helical LSD due to the price (<$800 shipped) and having read a lot of positive reviews on various platforms. I was happy with the apparent quality of unit:

My 125,000 mile 02Q looks perfect inside. No oil sludge or unusual wear. I've used OEM fluid, with 1 change at about 90,00 miles.

This being a 2006, I had the brass shift forks. I had originally ordered the steel forks, but was told that they were back ordered and would delay my project at least 2 weeks, I decided to go another route and strengthen the original forks as seen here: https://forums.tdiclub.com/index.php?threads/how-to-02m-02q-lsd-install.310279/. I replaced the failure prone rivets with 12.9 M8 cap screws, grinded the heads and sloppily welded to prevent loosening:

Drilled out the rivets on the stock diff. Lesson learned: start with the small pilot hole to help guide the larger bit (1/2" cobalt). Then fitted the ring gear to the Mfactory. Torqued the supplied hardware to 70ft-lbs with red loctite.

Checked endplay with no shim. Ended up being able to use the original shim (0.95mm). This pointed to the quality machining of the Mfactory, having the same bearing locations as the factory to the nearest 0.05mm.

Now on the one issue I discovered in my 02Q - the input shaft bearing. This is a common problem frequently discussed in MK4 R32 forums. On 02M and early 02Q units, the large ball bearing on the outer end of the input shaft has a tendency to have the outer bearing spin in the case. This leads to wear of the aluminum case which eventually allows the bearing to have axial play. In my case the input shaft was able to move in and out about 1/16". This resulted is hard shifting in and out of 1st and 2nd gear. If left unchecked, the case would continue to wear until the input shaft gear faces begin to grind on the alternating 1-4 and 5-6 stack gears, this is commonly referred to as the "02M death rattle." Later 02Q's have steel washers on either end of this bearing which seemed to prevent the issue. I fixed the issue by first installing one shim (0.65mm) then measuring the remaining play (in my case 0.25mm). So I needed 0.9mm shimming to eliminate play. I accomplished that by pickup another OEM shim and sanded both shims to 0.45mm. This eliminated the axial play and I applied Loctite 680 bearing retaining compound to the outside of the bearing to prevent further spinning which should permanently fix the condition.

All in all it was a really fun project. I don't have much of a review of the results yet because the car now badly needs an alignment (also replaced tie-rod ends) and I haven't yet put on my summer wheels.

On the 034 subframe mount - it is ridiculous that this mount is marketed as a solution for street cars. I had extreme vibration on 1st gear take off. I thought my glovebox was going to fall off. I drilled several relief holes in the rubber which calmed it down to the point that it's livable for now.

Last edited: